RITTER MACHINERY

American Made Woodworking Machinery

For over 50 years, Ritter has been a name synonymous with American made industrial woodworking machinery. Ritter has earned a reputation of reliability and dependability with its products, and also excellent customer service. Ritter’s signature reputation is for heavy, ruggedly built and user-friendly machinery. Today, Ritter is a recognized name in the worldwide woodworking industry and is one of America’s leading woodworking machinery manufacturers.

FND A DISTRIBUTOR REQUEST A QUOTE FIND SPARE PARTS

Check Out Ritter Machine Offerings

Pocket Hole Machines

Our industrial Pocket Hole machines are perfect for high production operations.

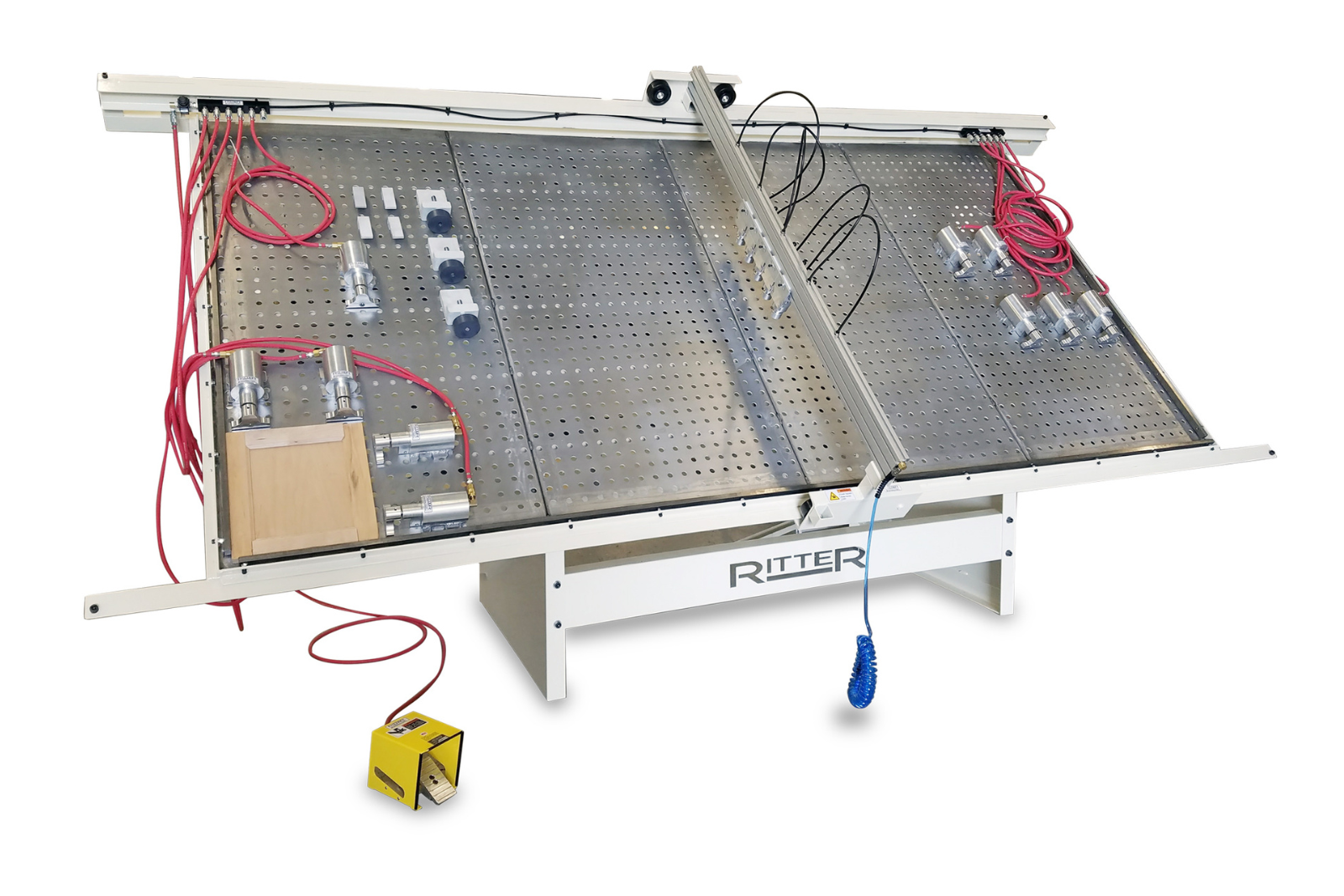

Face Frame Tables

These heavy duty Face Frame Tables are the industry standard.

Door Clamping Tables

Our versatile Door Clamping Tables come in a variety of sizes to fit any shop.

Line Boring Machines

Our time tested Line Boring machines bring consistency to every drilling operation.

Horizontal Boring Machines

Our horizontal borers are the perfect fit for applications from stiles and rails to furniture.

Edge Sanders

Our American made Edge Sanders are built to last and fit cabinet shops of any size.

Need More Information?

Give Ritter Machinery a call today or find your local Ritter Distributor here.

Nosotros Hablamos Español! Contacta Con Nosotros.